Moldflow

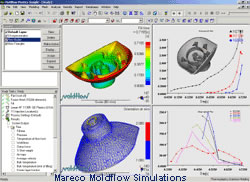

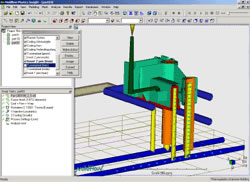

Mareco Kunststoffen B.V. uses the most comprehensive and latest "Moldflow Plastics Insight"™ finite element package to simulate the complex behavior of injection molded polymer melts. Analysis results are professionally interpreted using the years of experience and knowledge of our moldshop and injection molding department, and are used to predict and eliminate potential manufacturing problems before they even occur. In this way, excessive costs and time delays associated with manufacturing problems are avoided.

Available moldflow analysis modules

Analysis modules available:

- Fusion

- Flow -Filling and Packing

- Fiber

- Cooling

- Warpage

- Optimization

- Design of Experiments

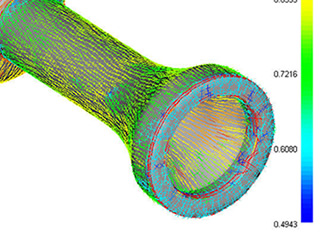

By using the fusion (i.e. Dual Domain) capability, we can perform detailed analyses directly on thin-walled, surface models imported from a CAD package. After applying the boundary- and process conditions, Mareco can simulate the Filling, Packing and Cooling stages of the injection molding process and predict post-molding phenomena such as part Warpage. Using the Fiber module, we can also analyse the flow of fiber filled thermoplastics and isolate its influence on the part warpage.

The Optimization analysis automatically determines the optimum velocity and packing pressure profiles, based on the material data, mold geometry, and molding machine characteristics. Design Of Experiments (DOE) makes it possible for us to automatically setup and perform a sequence of analysis, varying specified parameters of the injection molding process. The results are statistically analysed to optimize the processing parameters, ultimately resulting in optimized part quality and cycle-time.

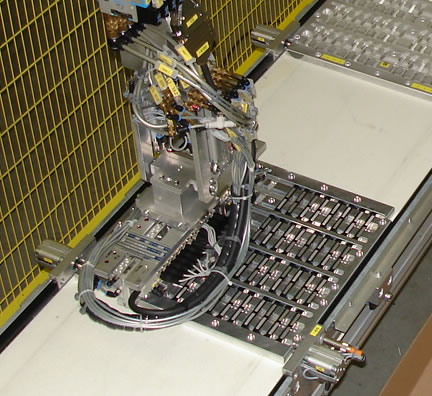

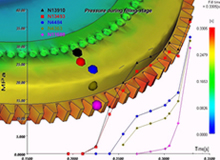

Analysis of pressure during filling stage

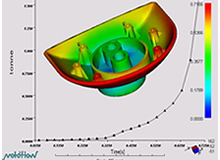

Analysis of clamp-force during filling stage

Experience and expertise in mold design and mold manufacturing

Analysis results are interpreted by our skilled people, using the many years of experience in mold design, combined with our expertise in mold manufacturing and injection moulding.

When used in the earliest stage of design, we are able to provide designers and engineers with the necessary insights and knowledge of how molten polymer propagates through the part cavity. By suggesting part/mold design modifications, in combination with material choice and processing conditions, we can assist you in constructing a part/mold which is fully optimized for the injection molding process. This ultimately results in reduced tool lead-times, optimized cycle-times and reduced costs.